Stone shop drawings are detailed plans for making and installing stone in construction. Stone fabricators or manufacturers create these drawings to guide the production process. They're essential to make sure the final product meets the design specifications.

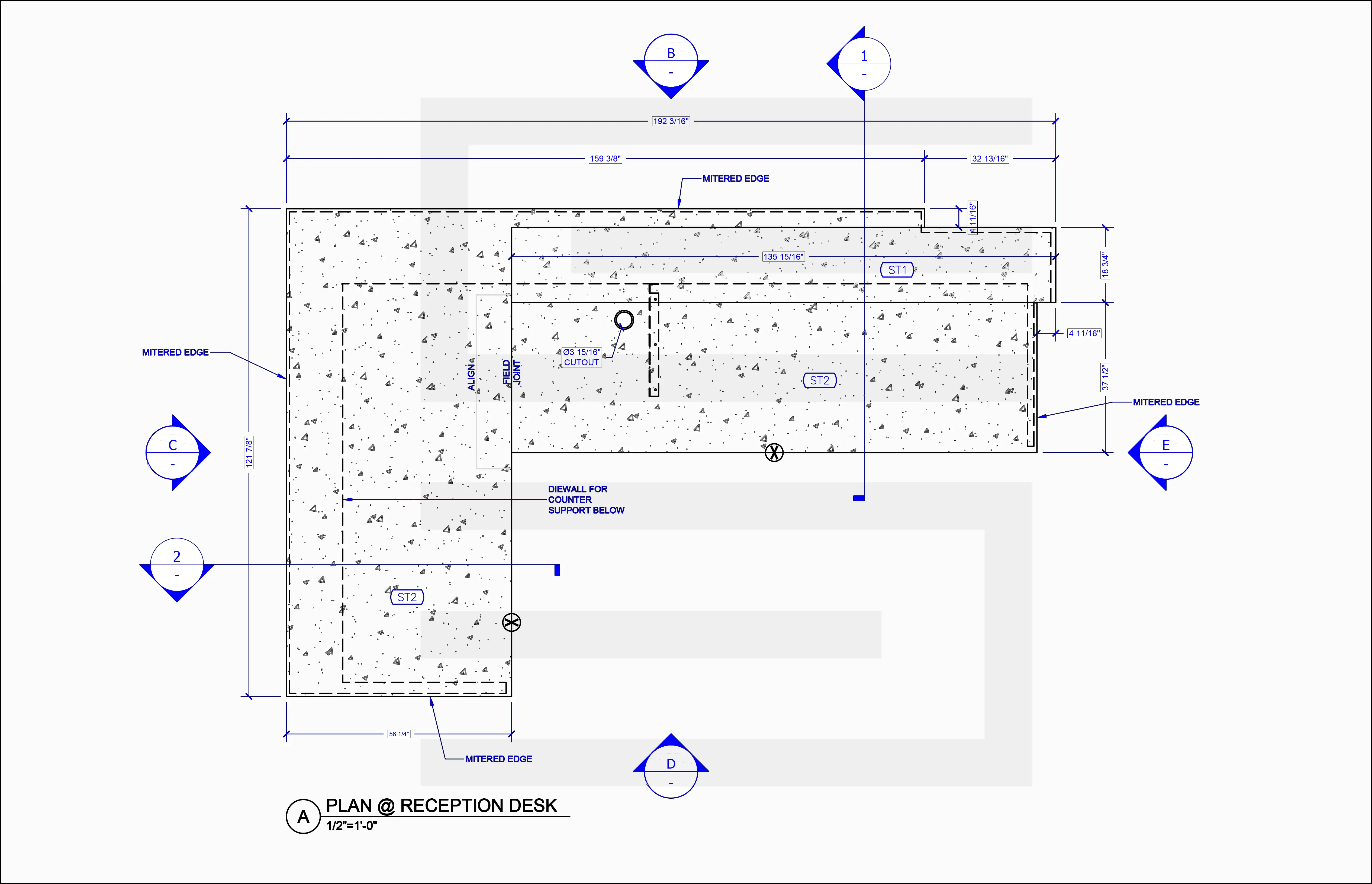

The plan view is a top-down or overhead representation of the millwork component. In the context of millwork shop drawings, a plan view often shows the shape, size. An elevation view provides a representation of the millwork component as viewed from the front, side, or back.

Sectional views provide a cutaway perspective of the millwork, revealing internal details and construction. Detail views focus on specific areas or components of the millwork, providing close-up illustrations of critical details. This helps ensure that fabricators understand the specific requirements for certain parts of the project and how different components are joined together.

Accurate measurements and details for each stone piece are carefully given to ensure it fits perfectly into the architectural design. This thorough information makes sure that each stone matches the requirements, adding to the overall strength and look of the project.

Stone shop drawings include the details of the edges of stone elements. It includes specifics like the kind of bevels, chamfers, or unique profiles used to shape the edges. This detailed information is important to make sure the stone elements match the design requirements. Differences in edge shapes and finishes play a big role in how the final product looks and functions.

The paragraph discusses how stones are connected and joined together. It explains the types of joints used and details their dimensions for a perfect fit. The document also highlights any special reinforcement needs and stresses the importance of understanding the structure for assembling stones. This approach ensures a smooth integration of components, providing both durability and a cohesive look in the final construction.

The document has detailed information about the precise cuts, intricate carvings, and careful detailing needed for the stone elements. It specifies the exact requirements and design details for the production process, including the specifics of each cut, the depth and precision of carvings, and overall stone detailing. This level of detail is crucial to make sure the manufacturing team accurately follows the design, achieving the desired look and quality in the final stone product.

The document gives detailed information about the stone to be used, covering its color, texture, finish, and other important specifications. The aim is to provide a clear and precise description of the chosen stone, making sure everyone in the project understands its characteristics. This detailed information is important for accurate procurement, fabrication, and installation, ensuring that the final result matches the planned design and aesthetic preferences.

Stone shop drawings give precise and detailed plans for the final product, ensuring accuracy in measurements and specifications. This helps prevent mistakes and reduces material wastage during fabrication.

Stone shop drawings show what the final stone product will look like in the overall structure. They help people make decisions and changes before actually making the stone elements.

Stone shop drawings are crucial for custom designs. They help plan intricate patterns, carvings, and unique shapes in stone fabrication. These detailed blueprints ensure precise execution, aligning the final stone product with specific design requirements.

Stone shop drawings serve as valuable documentation for the entire project life cycle. They provide a record of design decisions, changes, and specifications, which can be useful for future reference, maintenance, or renovations.

Copyright © 2024 Studio Precise. All rights reserved.